Built-In Bookcase

This project is a built-in bookcase, approx. 13 feet wide and 8 feet tall. It was made out of clear finished birch plywood with sapele solid wood front trim.

The customer asked for adjustable shelves to accommodate a range of different sized books and other memorabilia.

Finished bookcase, ready for adjustable shelves, books and momentos.

A total of 13 sheets of cabinet grade birch plywood was used. Here the sheets are being cut to size on a sliding table saw.

Rows of holes are drilled in the upright panels to allow for adjustment of the shelves to the client’s needs.

Panels with finished shelf pin hols.

“Biscuits” (pressed wooden discs) are used to reinforce the corner joints and assure proper alignment.

Components ready for assembly.

The boxes are squared up and the plywood back panels are installed.

Grooves were cut into the front edge of each shelf.

Solid wood trim, made from sapele, was machined with a matching “tongue” to fit into the grooves. This creates a stronger joint and also increases the strength of the shelf, reducing the chance for sagging under heavy load.

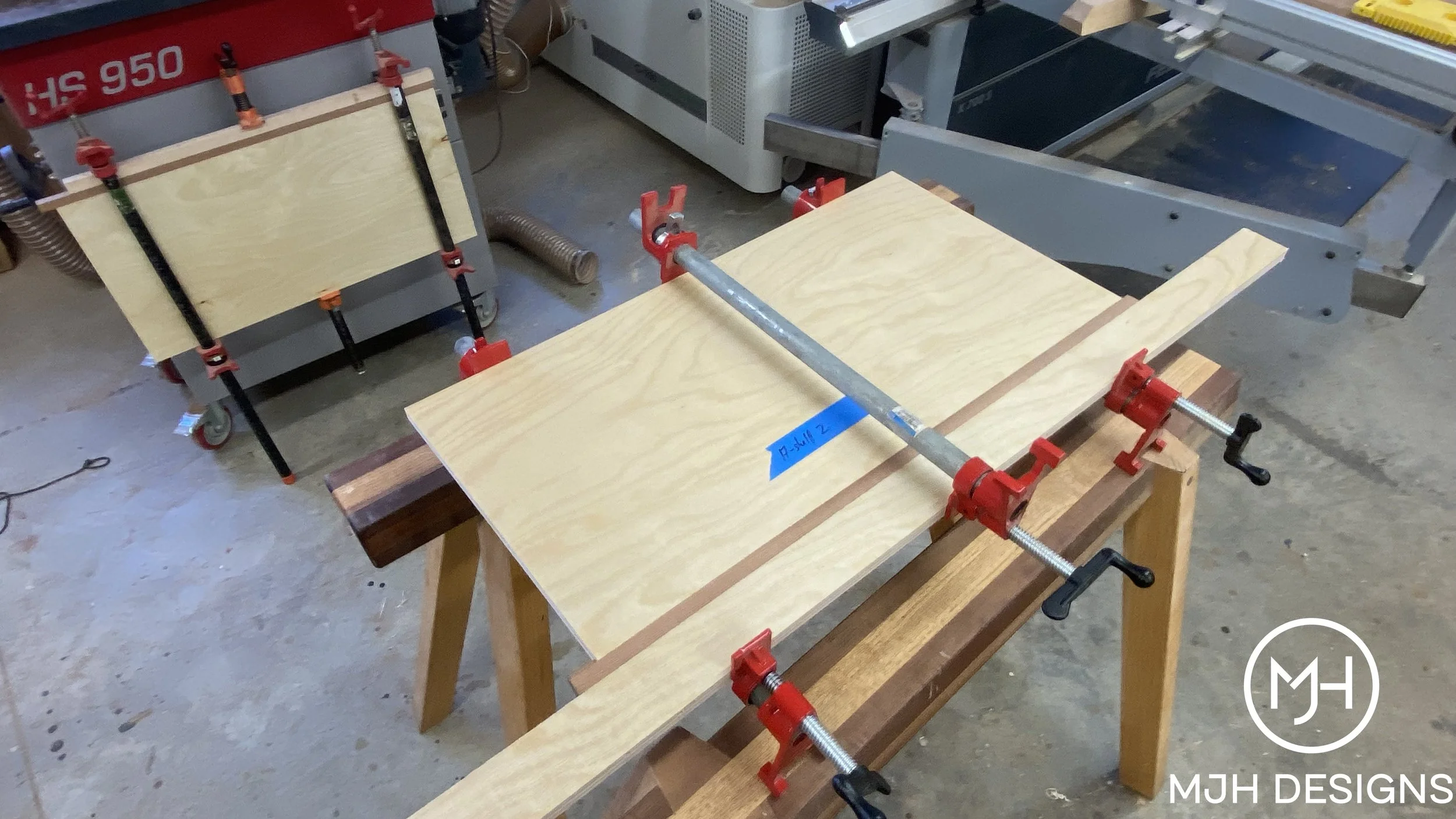

Edge trim pieces were glued to the shelves and clamped overnight.

The next day the trim was sanded, beveled and finished with hardwax oil.

Lamello Clamex connectors were used to attach the finished trim pieces to the plywood boxes.

Finished trim pieces - ready for install.

Trim is attached to the bookcase with Lamello Clamex connectors and glue - no nails needed.

Custom crown moulding was made on a moulder out of 1 1/4” thick stock.

Crown moulding - ready for oil finish.

Installation started with leveling and securing the base to the floor.

Two horizontal strips of plywood on the wall allow the boxes to be secured with screws.

The finished bookcase, with left and right sides scribed to the wall and the crown moulding along the top. The customer can now take his time to install the removable shelves in the correct positions to match his books and momentos.